48x48 Workhorse "The Rig"

- Thread starter JK47

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

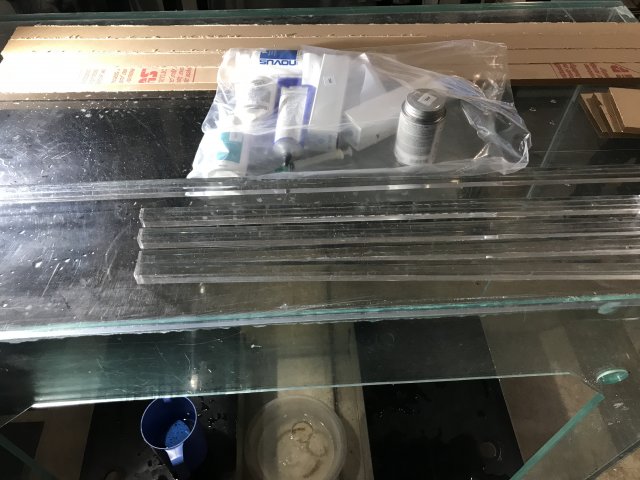

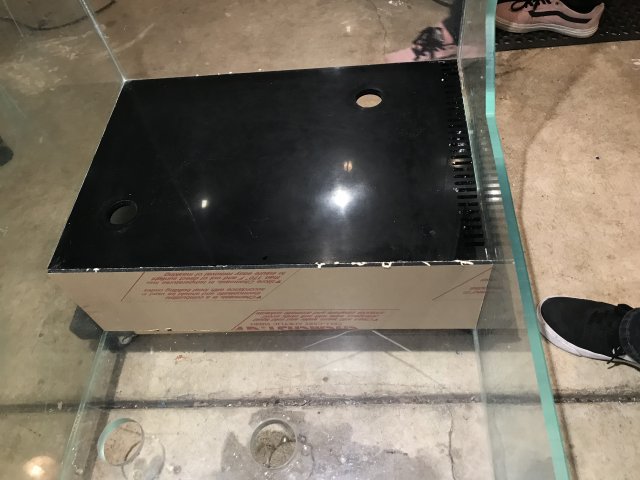

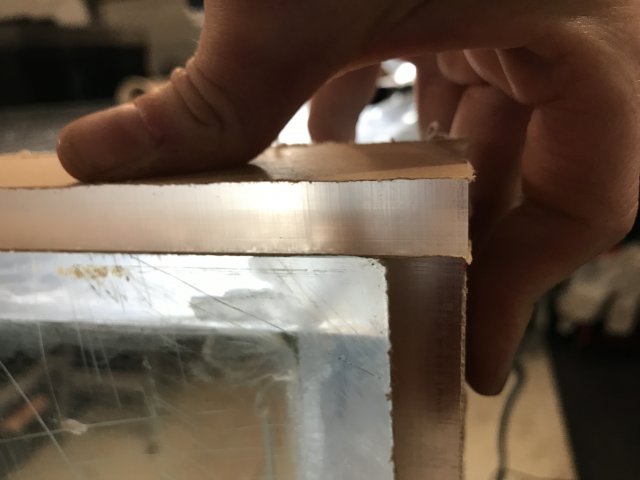

Are you using Weldon 40 to attach the rods?Using 5/8” square acrylic bar stock for the interior vertical seams. Inside the overflow tower:

View attachment 1302738

View attachment 1302739

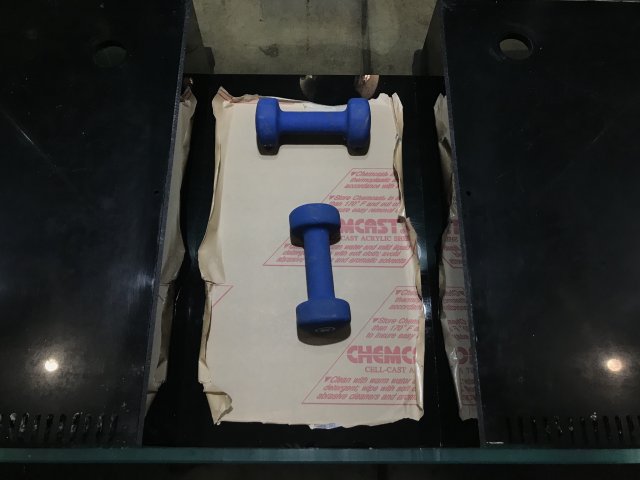

I had 1/2” cell cast cut down to two 1.5” x 48 7/8” and two 1.5” x 47 7/8” to reinforce.

View attachment 1302735

View attachment 1302736

I’ll get the strips on in the AM. Solid day

View attachment 1302742

I’m doing the same thing later today.

Not to be pushy but can’t wait to see how you do the k1 in the towers.

No worries at all. I’m working up the Ultima plumbing first. I should be knocking out the towers by next weekend

Are you using Weldon 40 to attach the rods?

I’m doing the same thing later today.

I didn’t use #40. Didn’t want the milky part on the front panel to be honest. I used #16. With 5/8” bar in interior and 1/2” cell cast on the exterior I’m not worried at all.

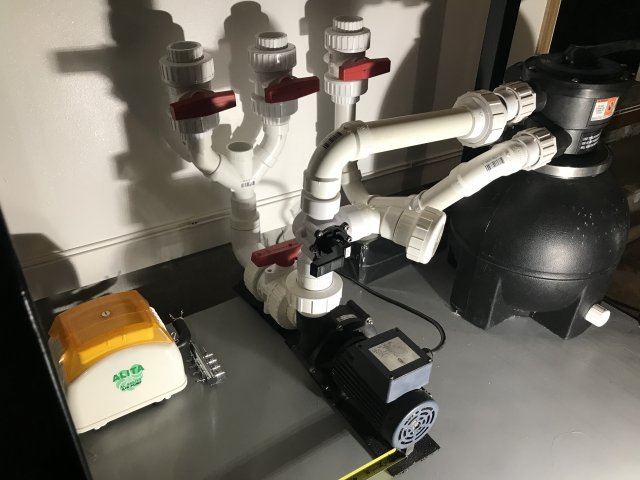

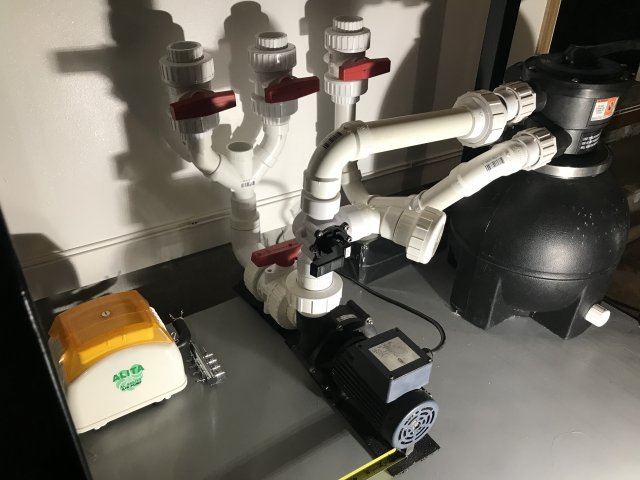

Tweaked the mock up layout to get the functions planned out with the valves in place.

Please ignore the awkward pipe from Ultima to union #3 I was playing with angles and will clean that up. The pump to Ultima return will have the union swapped to the other side and a black handle ball valve added as well.

The union valves will come up 8”-10” to be centered and in the stand. The middle red handle is the center reference. Three vertical pipes evenly spaced is the goal.

mrrobxc

^ better idea of the plumbing layout for ya

mrrobxc

^ better idea of the plumbing layout for ya

Access: Backwash union, head valve unit, pressure gauge, union valves and diverter valve/diverter sight glass are all visible and within reach. Functionality wise this is dialed. Just need to tuck it and clean it up

Please ignore the awkward pipe from Ultima to union #3 I was playing with angles and will clean that up. The pump to Ultima return will have the union swapped to the other side and a black handle ball valve added as well.

The union valves will come up 8”-10” to be centered and in the stand. The middle red handle is the center reference. Three vertical pipes evenly spaced is the goal.

Access: Backwash union, head valve unit, pressure gauge, union valves and diverter valve/diverter sight glass are all visible and within reach. Functionality wise this is dialed. Just need to tuck it and clean it up