1300 Gallon Plywood Tank Build

- Thread starter djseverson@yahoo.com

- Start date

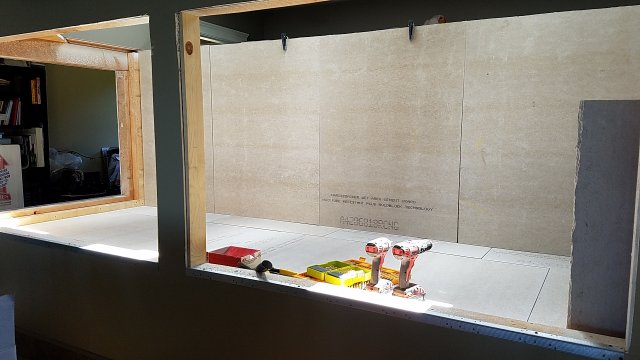

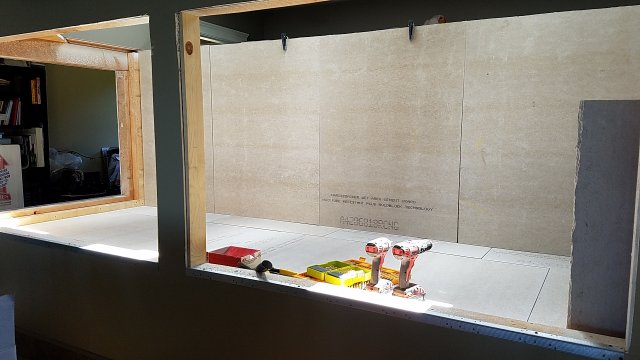

OK, here are the initial photos of hardie board installation in the the plywood frame. I do not think it was necessary to do this, but I wanted the extra rigidity of the frame. Since the plywood was installed with nails, screwing in the hardie will eliminate the nail pop risk. If I had chosen to use an epoxy water proofing then I would go this route for sure. I chose to water proof with blue max and I think the blue max would work fine directly to the plywood. Based on limited reading, I have seen the epoxy coated tanks typically fail due to stress fractures with the epoxy getting brittle. The liquid rubber tanks offer more flexibility against stress fractures, but tend to fail due to tears or punctures in the membrane. I am researching top coats now. Blue Max recommends a top coat for UV stability and I have seen other threads where it was top coated. I also plan to use protective sheets (pvc, plexi, abs, nylon, .. still need to price and decide) across the bottom and lower walls of the tank as protection against the sharp crushed rock I bought as a base substrate.

why not just putting 1/4" plexi in like building another tank inside this one? use the wood structure as support and the plexi as the waterproof barrier? tricky part might be the window to plexi meets if the window is glass. I have been thinking of doing this myself. but my windows will be plexi and much thicker than the sides and bottom.

Fair question, I don't know. Has anyone else tried this. Seems like it would be a sound way to go. Potentially you could even use non translucent sheets (I am going to meet with the plastics supplier and compare ABS, Acrylic, PVC, Nylon, etc.) on the non window sides as long as you could bond back to the window. The trick would be sealing the corner seams, but otherwise I think it would be cheaper and just as structurally sound. You would want slightly different framing than my tank. This was a result of having our house framing crew tackle the tank framing for me, but they framed the viewing windows as 2x4 supports and 6x4 header on the outside edge of the 2x6 walls. This leaves an extra ledge on the window side that you would want to be flush (for me, I used it as a framed channel for holding the glass above the substrate level, but lining entirely with Plexi, I would think 4 straight sides would be ideal.why not just putting 1/4" plexi in like building another tank inside this one? use the wood structure as support and the plexi as the waterproof barrier? tricky part might be the window to plexi meets if the window is glass. I have been thinking of doing this myself. but my windows will be plexi and much thicker than the sides and bottom.

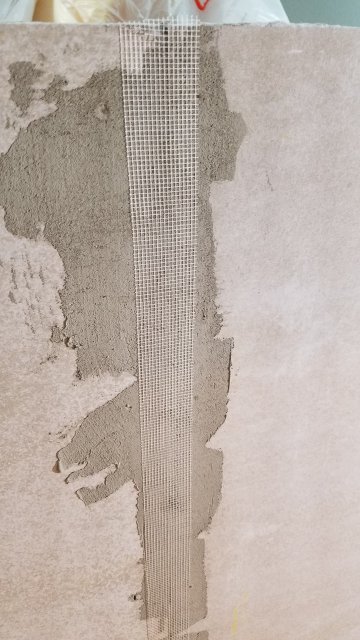

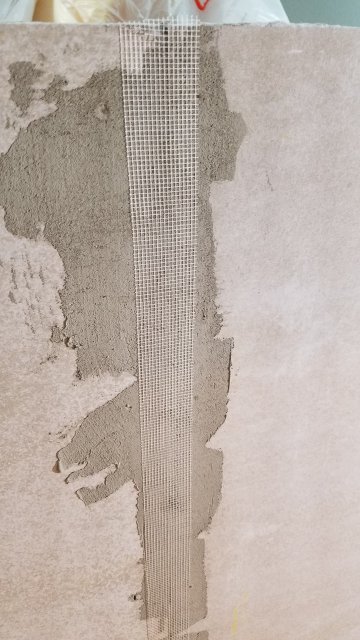

OK, here is the cement coated and thinset seamed tank. Some pictures show the holes drilled for bulkhead fittings for plumbing purposes. The holes cut in the sheetrock on the tank side of the front face wall are for mounting the front to back steel channel cross bracing. Originally I planned to use the Blue Max seam tape over the hardie board seams and screws. These seem solid enough that the top coat of bluemax should be stable without bluemax seaming tape.

I feel like I need a design/materials summary post coming up that lists out products and reasoning. Prior to the summary I will post a few part numbers and pictures of components I located and selected for the tank. Bulkhead fittings for example, most irrigation stores (at least my local shops) carry banjo bulk head fittings. They don't have enough thread bite to go through an 1.5" plywood tank wall. Spears makes a fitting for thicker tank widths, but they are pricey in the $60 + range for 1.5" adapter. Hayward also has adapters for thick wall tanks and they are a bit more economical in the $25 range, but I found availability to require a longer lead time. Lifeguard aquatics was the winner with 1.5 and 2" fittings for $5 to $7 on amazon. The reviews are mixed with some having a difficult time clamping down the seal. I am not there yet, but it would seem I should be able to locate another thicker gasket if necessary.

Here are photos of coat 1 of the bluemax. I am still looking at prior builds using blue max for reference on finish coat, durability, longevity and fish toxicity as I have seen mixed commentary. I used bluemax trowel grade in coat 1. I bought a 5 gallon bucket of the original blue max and the trowel grade. The trowel grade is designed to bridge larger gaps. I applied it with a 4" and 1" (for tighter corners) paint brush. Went on really easy, took about an hour to get this coat. A bit transparent, you see the thinset show up as darker regions through the 1st coat.

Here are photos of coat 1 of the bluemax. I am still looking at prior builds using blue max for reference on finish coat, durability, longevity and fish toxicity as I have seen mixed commentary. I used bluemax trowel grade in coat 1. I bought a 5 gallon bucket of the original blue max and the trowel grade. The trowel grade is designed to bridge larger gaps. I applied it with a 4" and 1" (for tighter corners) paint brush. Went on really easy, took about an hour to get this coat. A bit transparent, you see the thinset show up as darker regions through the 1st coat.

This part takes at least 24 hours between coats, so a bit slow. I am ordering plumbing parts, pumps, etc. Over the weekend I bought 1700 lbs of 3/8" crushed rocks to make my own substrate mix. I am using a custom mix of yellow, red, green, purple, and white crushed natural stone. My glass is in, but I am not ready to install it yet. I met with the plastic people, but need to talk with the bluemax people again before figuring out finish steps for the bluemax. I will post more details with part numbers, but I bought a little giant pond pump capable of 5500 gpm under 5 ft of lift at 300 watts 120volts. That seems pretty impressive, but I just found another pump that can handle similar volume at 200 watts. I am very excited to share my air injection test results. I bought three venturi valves and set up air infusion tests using the little giant pump. I don't see any need to use an air pump or blower, the venturi injector works well, now I just need to figure out how much air I want to inject and where.

Below are photos of the bluemax seeming tape on top of coat 1 of the blue max. Subsequent photos are of the second coat of blue max (trowel grade) over the seaming tape. originally I though I would use bluemax seaming tape over the hardie board seams, but after using the thinset over fiber glass seaming tape and then the bluemax over it, I didn't see reason to use the bluemax seaming tape. Incidentally I found a few imperfections that pealed off to the original substrate after just 1 coat. The trowel grade product did a good job of repairing the "hole" and after the second coat the repairs were hard to find.

Below are photos of the bluemax seeming tape on top of coat 1 of the blue max. Subsequent photos are of the second coat of blue max (trowel grade) over the seaming tape. originally I though I would use bluemax seaming tape over the hardie board seams, but after using the thinset over fiber glass seaming tape and then the bluemax over it, I didn't see reason to use the bluemax seaming tape. Incidentally I found a few imperfections that pealed off to the original substrate after just 1 coat. The trowel grade product did a good job of repairing the "hole" and after the second coat the repairs were hard to find.

Quick Status Update: I have been applying coats of Bluemax and preparing for plumbing, glass installation, substrate, access, extra reinforcement, and stocking. I also started a new job, so I will get photos posted this week of the Blue max coats and list out a summary of filters, pumps, venturi valves etc. that I am utilizing. I am going to work on glass seal options early this week and hopefully try to install the glass next week. Shooting for Water test by Mid August. Blue Max needs at least 7 days cure time after completion of coats. I have applied 10+ coats so far, which is excessive (and I need to watch my window frames to make sure I don't make the liner so thick that I can't install the windows) but I figure the blue max won't really save, so why not keep adding thickness. As you can notice in the above pictures the early coats were semi transparent, you saw darker contracts over thinset areas versus straight over the hardie board. At this point the color is much darker and much more consistent, almost with a metallic sheen. I will get photos uploaded this week.

Build is coming along great! Glad to see this resurrected.

I think your mystery fish is a Neolamprologus tretocephalus.