The more I look at this plumbing and mentally walk through how this would weld together, the more I think the unions need be used for your plumbing assembly ease, not just disassembly.

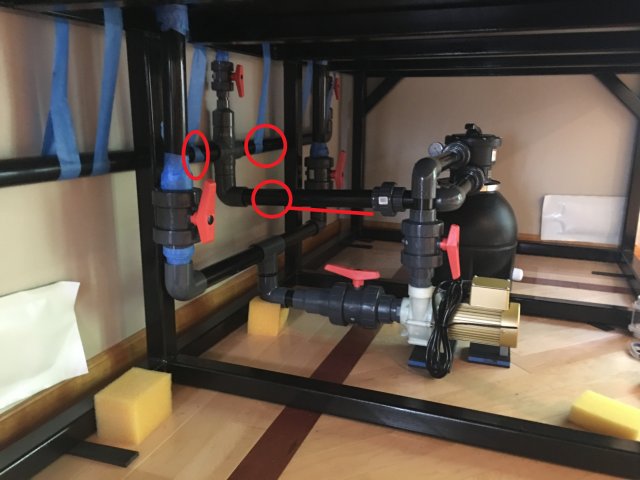

View attachment 1321949

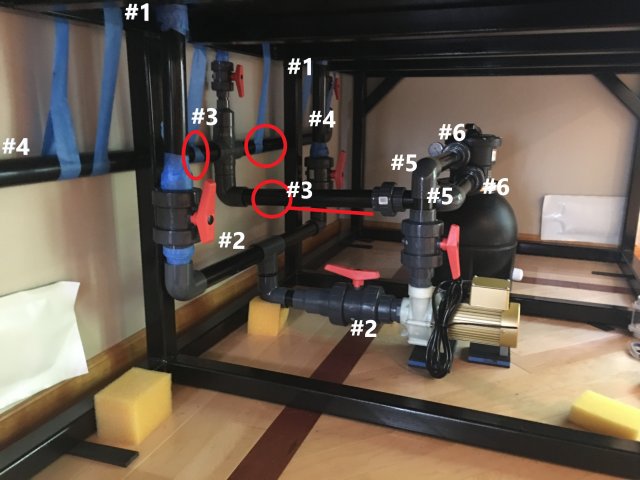

Comments:

- Ultima to return manifold: You should consider moving the union currently closest to the Ultima, closer to the manifold (flip what you have now). You want to plumb from a square point outward if you want all lines perfect.

- Manifold to returns: You should consider putting two unions just after the middle tee as well. It's much easier to plumb to short distances and hook up a union than to keep long stretches square and true.

Doing the above will let you solvent weld in the middle (center reference) and plumb out from there. Do not plumb from Ultima to tank, plumb tank to Ultima. If you have to move 1" or so for a mistake, its much easier to scoot an Ultima than drill and patch a new tank or replumb. The downside of working with sexy plumbing is perfection is much harder and there little room for mistakes all while having the eye drawn to it.

Lastly when mocking up/rough in your plumbing, make sure the pipe seats to the fitting socket depth (much easier with this combo than regular schedule 40) or that the additional length that isn't seated will be accommodated for via pipe length. Every 1/4" you are off for one fitting will carry through until it is off inches at the other side. Hence why working from center reference out and plumbing to unions as you go. Must easier to rebuild a piece that cut out and redo.