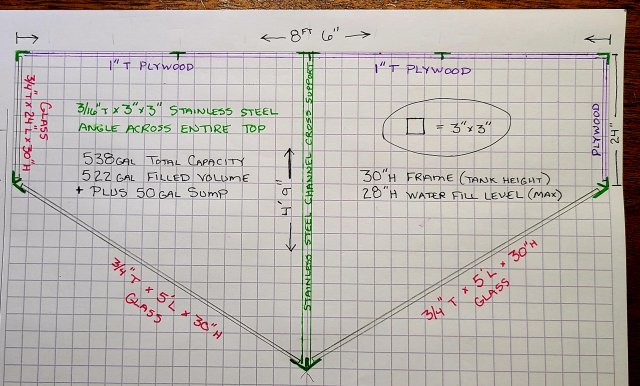

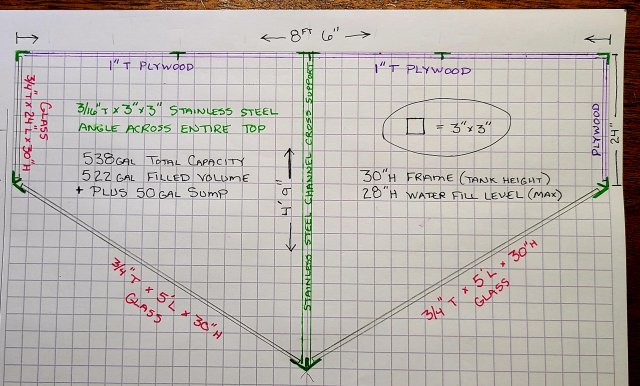

I'm in the process of designing my 500+ gallon tank with overflows and a 50 gallon sump.

It's an odd pentagon shape - 8.5' x 5' (should allow adequate turning radius for larger fish).

Please look at my drawing and provide me with any comments, pointers or tips. GOOD, BAD, or UGLY!

The entire frame will be custom made with 3/16" thick stainless steel ( in green).

The 2 front main glass panels will be 5ft wide x 28in high x 3/4" thick.

HERES WHAT I'M LOOKING TO HOUSE:

1 - Tiger Shovelnose Catfish

1 - Lima Shovelnose Catfish

1 - Spotted Gar

1 - Ornate Bichir ?

1 - Black Shark

1 - Leopard Sailfin Pleco

2 - Stingrays

2 - Oscars

1 - Clown Knife

1 - Short Bodied Red Tail Catfish = (Optional - Man I'd love to try to fit one of these in!)

THANKS IN ADVANCE!!

John

It's an odd pentagon shape - 8.5' x 5' (should allow adequate turning radius for larger fish).

Please look at my drawing and provide me with any comments, pointers or tips. GOOD, BAD, or UGLY!

The entire frame will be custom made with 3/16" thick stainless steel ( in green).

The 2 front main glass panels will be 5ft wide x 28in high x 3/4" thick.

HERES WHAT I'M LOOKING TO HOUSE:

1 - Tiger Shovelnose Catfish

1 - Lima Shovelnose Catfish

1 - Spotted Gar

1 - Ornate Bichir ?

1 - Black Shark

1 - Leopard Sailfin Pleco

2 - Stingrays

2 - Oscars

1 - Clown Knife

1 - Short Bodied Red Tail Catfish = (Optional - Man I'd love to try to fit one of these in!)

THANKS IN ADVANCE!!

John