. . .. Diy overflows can be a ticking time bomb waiting to go off and most hobbyist will recommend to drill the aquarium and install a bulkhead instead.

Ulu

Ulu

is our resident diy overflow guy . . . .

Thanks, but not sure if that's an honor, or if so one I can/should claim.

@riuglav

YOU need a valve to throttle the drain, at the sump end, to control the flow once it siphons. that eliminates the huge gush once it siphons fully.

If you get a trickle, you're not siphoning efficiently. The water level must drop 1.5" to 2" between the tank level and the "T" in your standpipe.

I have done this several different ways, on at least ten tanks. You can see my efforts posted here and on Fishlore in "Meet The Fish" but I will try to condense my advice.

First, drill the tank or have it done, if you can. I have some tempered glass I simply cannot drill, hence the overflow siphon devices are a must.

For a 55g tank with 1" pipe from the pump, I have THREE 1.5" dia siphon overflows.

One is always nearly dry but is un-throttled. That's the safety drain and just barely trickles. The others are throttled at the sump end. They are redundant, but drain at slightly different levels.

I always have a weir in the tank. It doesn't need to be glued in. I use a piece of pipe with a foot glued on the bottom & I weight the foot with gravel. By putting some gravel under the foot too, I can raise the level of the weir, and thus the tank. I don't depend on that outside "T" to set my level. That sets the flow rate, modified by the throttle below.

Also:

-The design you illustrate is impossible to clean and will plug up soon with goo from algae, snails, food starches, etc. Make sure you can push a brush thru the pipes, even if you must add a union for access.

-To mitigate that I like to use multiple 1.5" dia min outflows. A service drain and a "wet" emergency drain is the minimum recommended, and you ALWAYS need a GOOD Quality throttle valve on the sump end of the drain. A cheap valve will be difficult to adjust for a smooth flow.

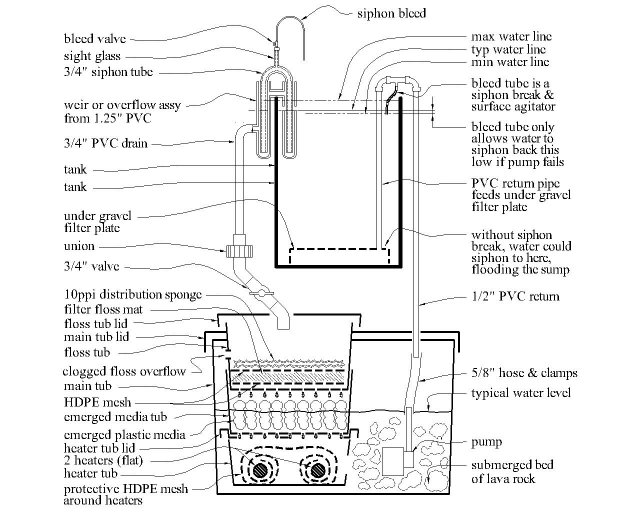

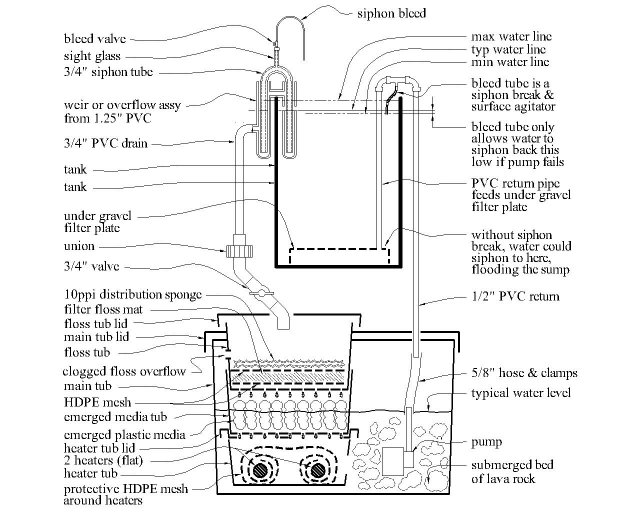

This shows a diagram of my first VERY small siphon-overflow sump. It is schematic and doesn't show the safety drain (which is just duplicating the drain, but has a higher weir setting.)

Key things in the design are:

- that the sump should not be able to flood the tank. It should suck air first, and raise the pump as required, or lower the sump water level. If the drain stops for any reason, the tank should fill up that last empty inch or so, and then the pump spits air. You will hear this and go fix the drain, or replenish evaporated water as required.

- that the return hose must bleed air if the pump stops, so it cannot back-siphon and flood the sump. The bleed adds surface circulation while he pump is running.