So I had my 4 point measurements all set on the side of the stand and then it hit me, maybe if I can get some 40 breeders to fit I could do a 6” hole saw on both tanks grab some unseals and just connect two 40’s. This would actually be cheaper in tank and give me 5 more gallons, but I’d be dropping some cash for the hole saw and uniseals. Anyone tried anything similar to this?

New 300G Setup

- Thread starter Denon

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why wouldn't you just hard plumb them together with bulkheads and PVC pipe? Would last longer if you could get hard plumbing in there.

You could do the 2 40s and merge them into 1 sump, that just sounds like a giant pain. Uniseals correctly size require quite a bit of force to properly seat the pipe and that would suck to do under a stand.

Can you go vertically? How tall is your stand? Could nest some waterproof storage totes, or even a couple 40B and have it flow down instead of length wise.

Can you go vertically? How tall is your stand? Could nest some waterproof storage totes, or even a couple 40B and have it flow down instead of length wise.

You could do the 2 40s and merge them into 1 sump, that just sounds like a giant pain. Uniseals correctly size require quite a bit of force to properly seat the pipe and that would suck to do under a stand.

Can you go vertically? How tall is your stand? Could nest some waterproof storage totes, or even a couple 40B and have it flow down instead of length wise.

Tested last night and I was able to get a 40 gallon breeder in the stand. Stand is 36" high (internal probably 34"ish) and 96" long. I have never worked with uniseals so I'll likely just go with bulkheads and I like you're idea of going vertically. Any recommendations on what to use to raise one of the 40's up?

Got my 75 swapped out for two 40's at petco. They were really nice about it, even though the dollar per gallon sale ended last week since when I bought the 75 it was at half price they still were able to exchange them for me. Interestingly she said the 40's are no longer dollar per gallon either and are now half priced. Dollar per gallon starts at 20.  Thinking I may build something like what

Thinking I may build something like what

Randys

did for under his stand under the 40. Just need to make sure I don't get it too high and can still access the tank for maintenance etc.

Randys

did for under his stand under the 40. Just need to make sure I don't get it too high and can still access the tank for maintenance etc.

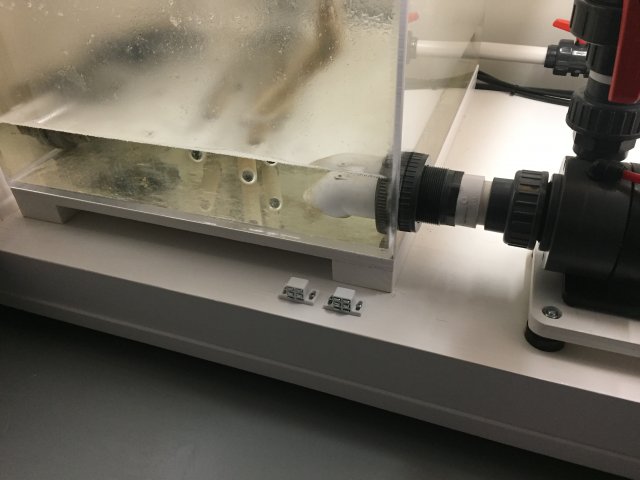

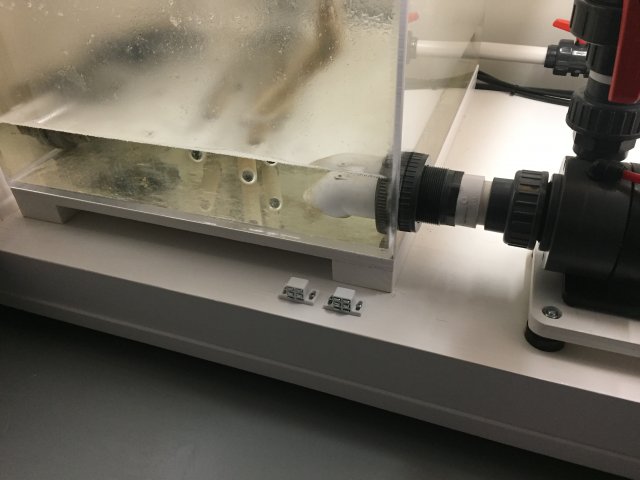

I built short risers for the sumps in my 90 and 300 also.

Initially I did it to adjust the level of the return pump outlet to the bottom of the sump tank but I also found out it's way easier to sop up any spill you may have in the cabinet.

It's a fine line though. The higher the riser the less head room you have on top of the sump.

Initially I did it to adjust the level of the return pump outlet to the bottom of the sump tank but I also found out it's way easier to sop up any spill you may have in the cabinet.

It's a fine line though. The higher the riser the less head room you have on top of the sump.

Haha, its coming. Right now I need to get a nice day to markup and drill it. So the side shot on page 3 is the best I can do until I get it drilled and get the crew back to help me tip it back right side up and move it into the house. In the meantime I've been playing around with different height levels for the sump.i need to see the full frontal! show us the 300g!!!

Tested last night and I was able to get a 40 gallon breeder in the stand. Stand is 36" high (internal probably 34"ish) and 96" long. I have never worked with uniseals so I'll likely just go with bulkheads and I like you're idea of going vertically. Any recommendations on what to use to raise one of the 40's up?

I would "stagger" them like stairs, so the top one is resting partially on the bottom one. Then opposite end of the top one could be supported by 2x4s or cinder blocks. The top tank having access being 100% mechanical, then place bio, heater and return pump in the bottom. I'd do a bulkhead out the side of the top into the bottom tank so it can be easily removed should the need arise. But my hope would be to keep all debris in the top tank. Then, worst case it is disgusting stop the return pump, remove the mechanical tank and hose it out then replace. Easy peasy maintenance.

Based on the measurements it will be too tight to go that high and still be able to pull out the top tank, but I do like the concept and will play around with stepping some more to see if I can get something that is high enough to provide me enough space to still access and perform maintenance on the top tank, and not have to drill the bottom tank.I would "stagger" them like stairs, so the top one is resting partially on the bottom one. Then opposite end of the top one could be supported by 2x4s or cinder blocks. The top tank having access being 100% mechanical, then place bio, heater and return pump in the bottom. I'd do a bulkhead out the side of the top into the bottom tank so it can be easily removed should the need arise. But my hope would be to keep all debris in the top tank. Then, worst case it is disgusting stop the return pump, remove the mechanical tank and hose it out then replace. Easy peasy maintenance.